The world’s scientific community is working hard to improve and master the use of perovskite (PK) layers, a very promising technology both for the realization of tandem cells, especially perovskite/silicon, and for the realization of thin-film devices, all perovskite or in combination with other thin-film technologies. Reflecting this particularly dynamic world race, power conversion efficiency (PCE) records, often obtained on very small surfaces, are currently rather frequent, and exceed 29% and 25% for tandem and single junction PK cells [1], respectively.

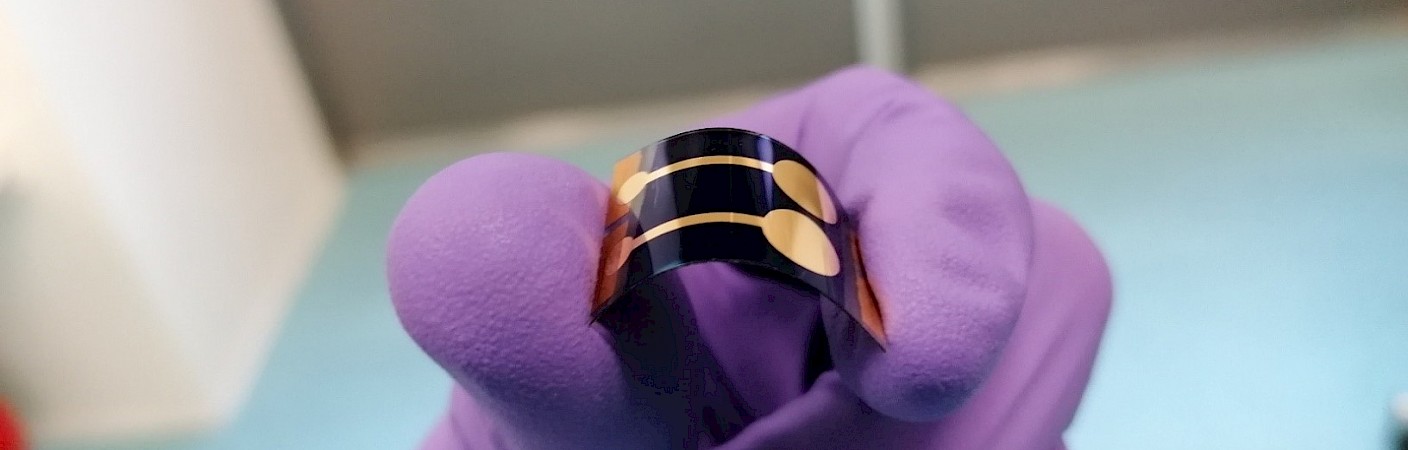

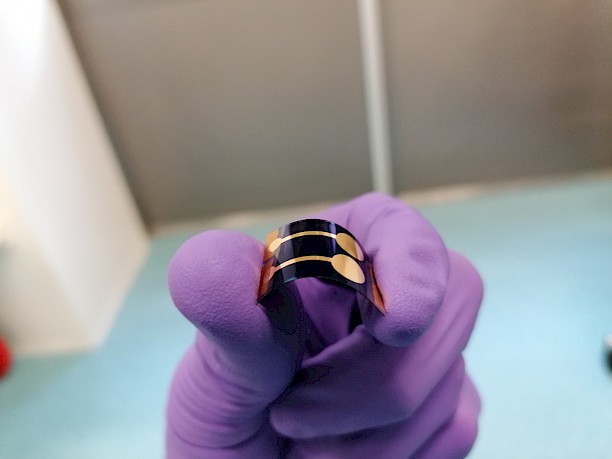

Perovskites excite the community not only for their high performance, but also for the advantage to be produced using solution processed methods at low temperatures (below 150°C). These remain as key factors to further increase the attractiveness of this technology by meeting the criteria of industrialization and competitiveness. CEA at INES is conducting a work on the development of low temperature process for perovskite solar cell fabrication within the framework of the European APOLO project, whose objective is to develop single-junction flexible Perovskite photovoltaic modules.