The CEA at INES is developing new generation inverters to reduce cost, improve energy performance and support the power grid. The compactness of these objects is also an issue in order to control the impact on the installation and maintenance costs of power plants, and to minimize the use of materials.

Our research focuses on electronic architecture and uses "large gap" semiconductors such as silicon carbide (SiC) and gallium nitride (GaN), in particular those developed in the CEA-LETI laboratories in Grenoble.

GaN technology is one of the so-called "wide-gap" technologies (broadband semiconductors), which push the limits of power semiconductors using silicon.

It allows for miniaturization and increased energy efficiency while reducing costs.

The photovoltaic and automotive industries (with electric vehicles) are the main growth drivers for these new converters based on GaN or SiC semiconductors.

CEA-Leti has state-of-the-art epitaxy (600V and 1200V) and technology to produce GaN 600V diodes and power transistors that outperform silicon equivalents. With this coplanar technology, it would be possible to make the power component "smarter" with protection (temperature, voltage, current, etc.) and control (driver) functions. It is also possible to design bidirectional voltage interrupters which do not exist at present.

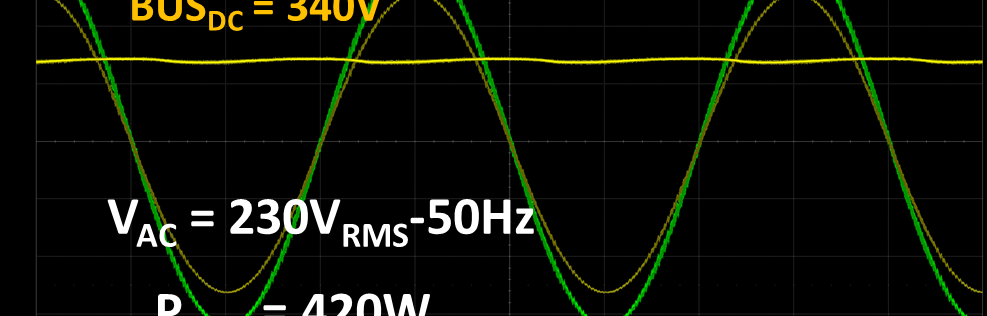

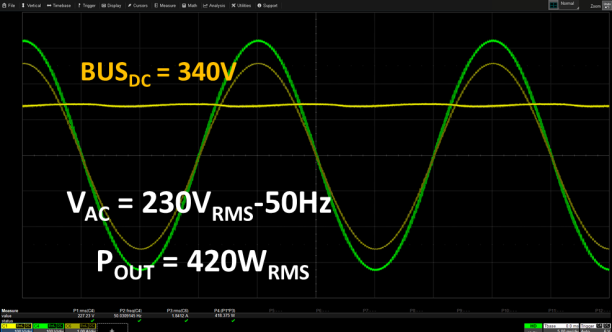

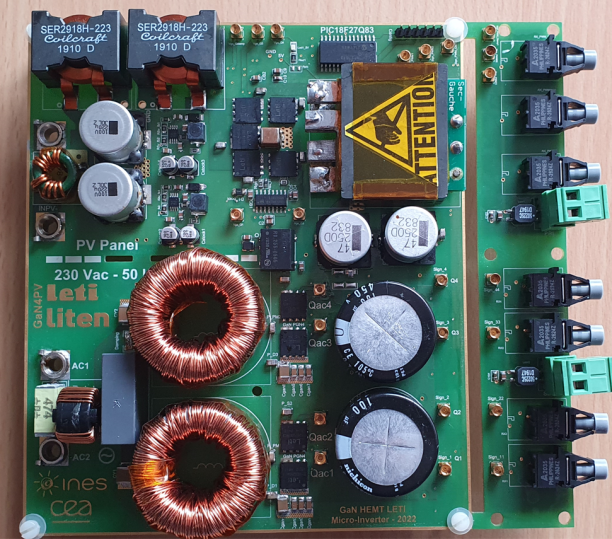

The CEA at INES has built a high-temperature dynamic characterization bench for these new GaN transistors, as well as the first prototype of a 400W photovoltaic microinverter using the transistors made by CEA Leti's Components Department. This microinverter consists of two conversion stages:

- A DC/DC stage comprising 5 GaN 100V transistors

- A DC/AC stage comprising 4 GaN 650V transistors